Lime kiln designs

Practical Action

Description of the Kilns

This leaflet considers the production of quick- lime in vertical shaft kilns fired with oil.

Another leaflet in this series describes kilns which can be fired with coal or wood.

Vertical shaft kilns work on a very simple principal. The raw material is fed in at the top of the

kiln and the product is withdrawn from the bottom, causing the material to move slowly

downwards through the kiln. Heat to calcine the material is introduced roughly in the middle

of the kiln and therefore any" material above is preheated by rising hot exhaust gases, and any

below cooled by incoming air. In this way, material entering the kiln at the top is first

preheated, then calcined and finally cooled during its passage through the kiln.

For vertical shaft kilns the feed rock should be crushed to sizes between 40 and 150 mm.

Since it typically takes 1.75 kg of limestone to produce 1 kg of lime the transportation of

the raw material should be kept to a minimum. Therefore lime kilns are normally located

close to the limestone quarry.

The use of oil as fuel has both advantages and disadvantages compared with the more

traditional methods using coal or wood as a mixed feed with the limestone. The main

advantage is that there is normally no contamination of the lime with soot or ash. Better

control can also be achieved over kiln temperatures ensuring a better quality, more valuable

lime. The main disadvantages are that the kiln design needs to be more sophisticated, and

therefore is more expensive. In some locations wood or coal is both cheaper and more readily

available than oil. The latter point is significant in that use of oil in these locations may

require importation. In oil-

producing countries the use

of oil as fuel could be

practicable even when the

quality of lime is of

secondary importance.

Practically all types of fuel

oil can be used. In the case

of bunker C oil, this has to

be preheated to 100-

120°C to make it less

viscous. The use of waste

oil, such as old engine oil,

is not recommended for

very high quality lime, but

may be acceptable for lime

of lower quality. It may be

necessary to mix waste oil

with a quantity of fresh oil,

as it is rarely available in

sufficient quantities for a

continuous production run.

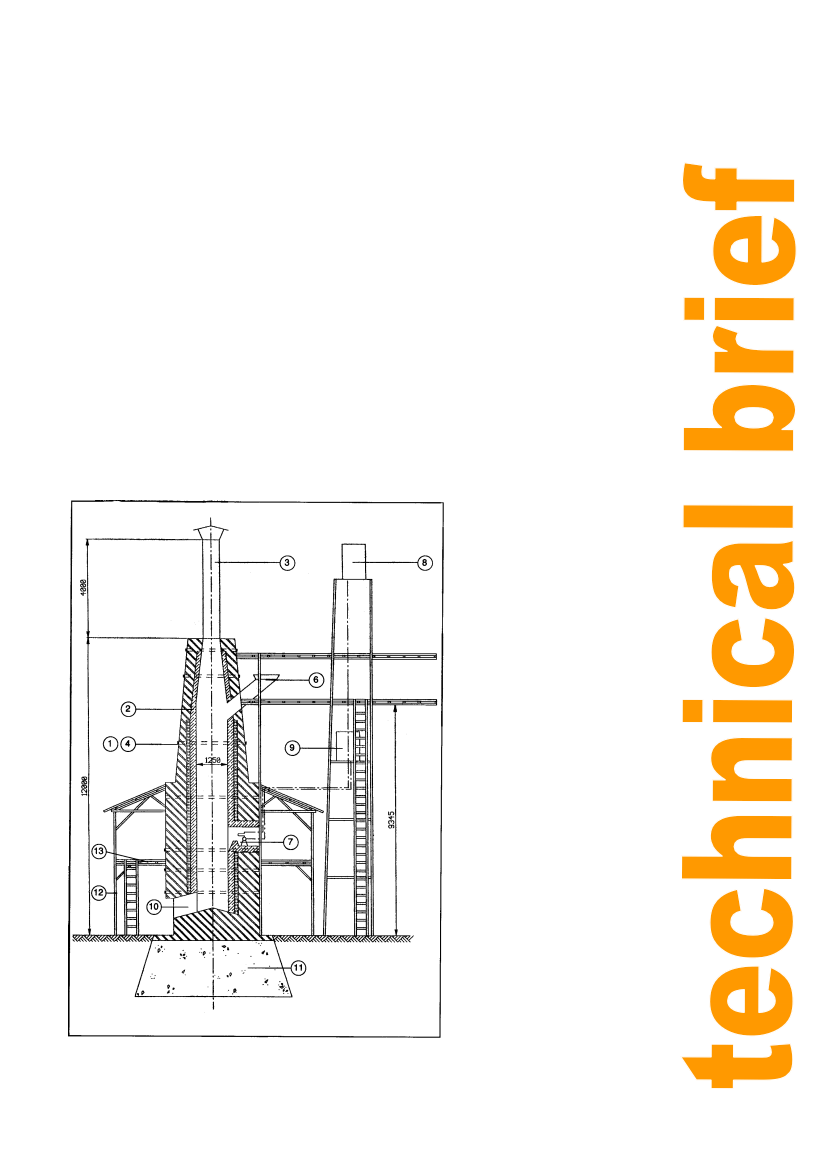

Figure 1: 6 ton per day kiln.

2